2024 Performance Highlights (S)

- At least one meeting of the Port Facility Security Committee was held in 2024 to review the overall port facility security assessment and security plan.

- Port facility security drills and exercises were conducted once every quarter in 2024, with a total of at least 36 sessions across the entire port area, totaling 36 times.

- Each branch office conducted at least one VTS personnel training session, totaling four sessions.

- For ongoing construction projects, with a total of 83 projects under jurisdiction in 2024, each branch office conducted at least one monthly inspection of each project, while the headquarters conducted one quarterly inspection of each branch office, achieving a 100% inspection rate for all projects.

- The frequency rate (FR) of severe workplace accidents and occupational diseases* resulting in disability is 0.

- *Severe workplace accidents and occupational diseases: workplace injuries resulting in death or inability to recover health within six months.

- The company has organized a total of 600 workplace-related activities for employees. Promoting safety in international port terminal cargo handling operations: The company has established a guidance plan to conduct safety promotion activities every six months, targeting port cargo handling operators or occupational safety personnel. In 2024, the number of participants in safety promotion activities reached 481. Annual audits and inspections were conducted 12 times (individual and joint audits), with 21 promotional activities and 48 audits and inspections being carried out, achieving the annual execution rate target of 100%. The target participation rate for diverse health promotion activities was 65%, with an actual achievement rate of 79.52% in 2024, meeting the annual target.

Comply with the SDGs

- SDG3【SDG 3.8】

- SDG8【SDG 8.8】

Management Policy

Covered material topics

- Safety management of port Operations

Policy

- Occupational Safety and Health Policy

Management Evaluation System

- Workplace Safety【Risk Assessment and Management Mechanism】

- Employee Health Management

- Safety Management of Port Operations【Disaster Prevention and Response Plan】

- Occupational Safety and Health Policy

TIPC is committed to enhancing occupational health and safety management performance and promoting workplace safety and health. Guided by the core principles of caring for employees, contractors, port operators, and implementing occupational health and safety measures, we actively prevent occupational accidents and strive to provide employees and stakeholders with a safe and healthy working environment. We continuously cultivate a safety culture with the participation of all employees and promote a "safety and healthy" friendly workplace culture to achieve the ultimate goal of zero occupational accidents. Our aim is to shape the image of TIPC as an internationally recognized enterprise with excellent workplace safety and health standards.

.png)

Occupational Safety and Health Policy

Occupational Safety and Health Management System

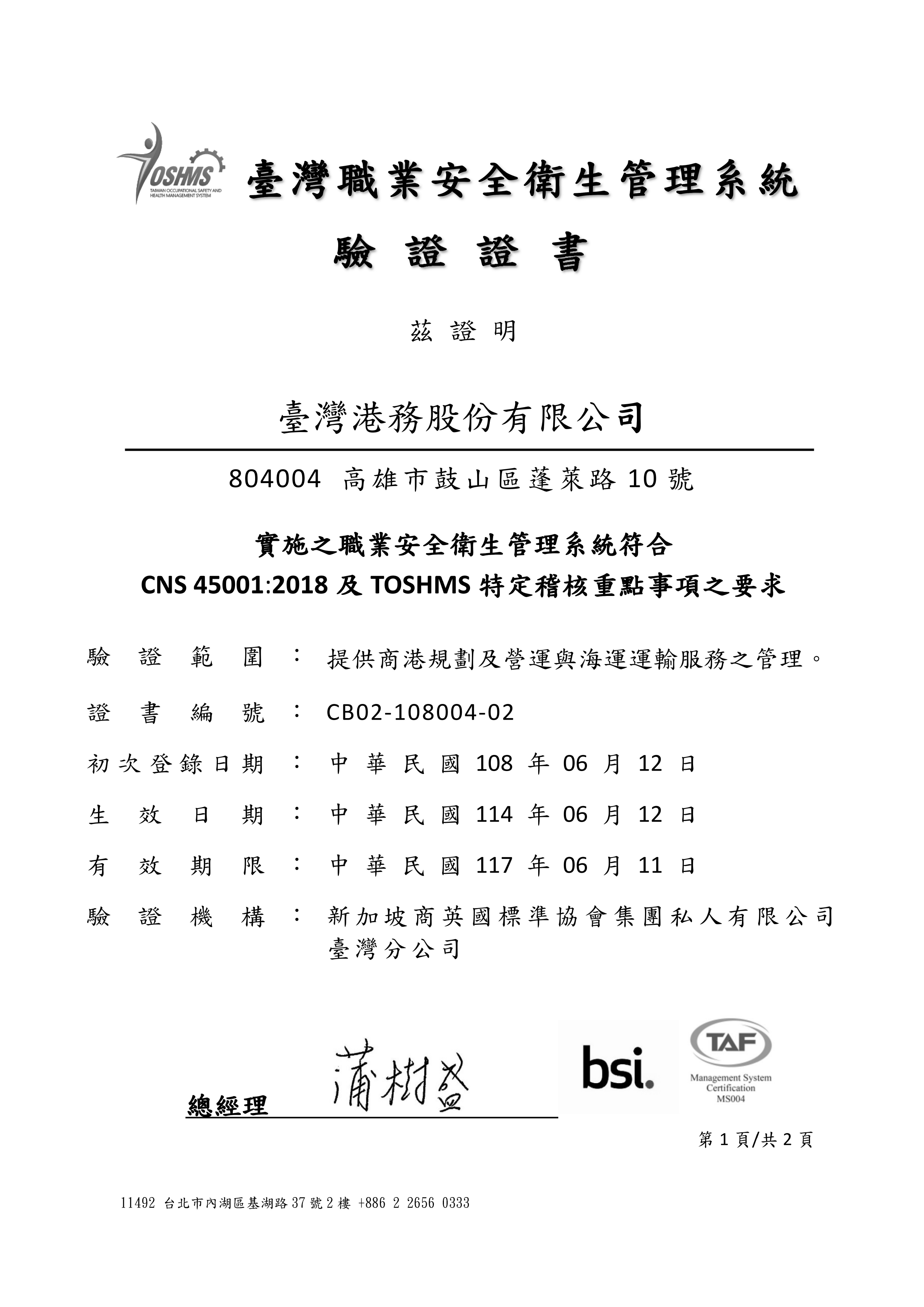

TIPC (including the headquarters, Keelung Branch, Taichung Branch, Kaohsiung Branch, and Hualien Branch) successfully obtained ISO 45001 / TOSHMS dual system certification in May 2022 (valid from June 12, 2022, to June 11, 2025), and all branches have passed the BSI annual follow-up audit from 2023 to 2024.

The occupational safety and health management system of TIPC covers the headquarters and all branches. The headquarters is responsible for coordinating and planning the commercial port development, construction, operation, and maritime transportation service management of the company and its affiliated branches, as well as related personnel. Each branch office is responsible for managing port-related operations and activities, including wharf, port, and project management, within its jurisdiction. The scope includes: Keelung branch office (including Keelung Port, Taipei Port, and Suao Port), Taichung branch office (including Taichung Port), Kaohsiung branch office (including Kaohsiung Port, Anping Port, Budai Port, and Penghu Port), and Hualien branch office (including Hualien Port).

ISO 45001 Certificate – Headquarters of TIPC

Taiwan Occupational Safety and Health Management System (TOSHMS) Certificate – Headquarters of TIPC

Occupational Safety and Health Committee

This committee consists of one chairperson and nine to twenty-one members. The chairperson is concurrently served by the Chairman of the company or his/her representative, who presides over all committee affairs. Committee members are divided into appointed members and labor representatives. Among them, six to fourteen appointed members are designated by the Chairman or his/her representative, including senior executives from the first-level units of headquarters, vice presidents of every branch, and medical staff, etc. There are three to seven labor representatives, who must constitute more than one-third of the total number of committee members, elected (or nominated) by the trade union. The term of service for committee members is two years, and they may be reappointed upon expiration. This committee meets once every three months to address matters related to its responsibilities. In accordance with the "Management Review Procedure," it regularly reviews changes and compliance with regulations and other requirements during management review meetings or occupational safety and health committee meetings, and retains relevant operational records in accordance with the "Document and Record Management Procedure." Additionally, the implementation progress of all objectives is reported to the committee by the responsible department every quarter for review to ensure management effectiveness.

%20(1).png)

TIPC Occupational Safety and Health Organization

Workplace Safety

Risk Assessment and Management Mechanisms

Pursuant to the 'Hazard Identification and Risk Assessment Procedure' of the company's ISO 45001 Occupational Health and Safety Management System, hazard identification and risk assessment are conducted for critical operations or work with higher potential hazards. In 2024, following hazard identification and risk assessment, fall risk among subcontractors was identified as the primary hazard type. To reduce the occurrence of falls, five high-risk disaster management workshops were conducted. Through thematic discussions, nine improvement measures were developed, including the introduction of technological risk prevention and establishment of the 'Occupational Safety and Health Cloud' inspection software, which were submitted for review at the annual management review meeting. The effectiveness of all hazard and risk assessment control measures was confirmed, serving as the basis for annual goals and management plans. This aims to continuously improve the occupational safety and health management system, implement necessary control methods, and maintain risks at an acceptable level, thereby enhancing occupational safety and health performance and striving for a safe, accident-free environment.

|

P(Plan) |

D(Do) |

C(Check) |

A(Act) |

|

Conduct planning, control, supervision, corrective measures, audits, and reviews to ensure compliance with occupational safety and health policy requirements and maintain the applicability of the occupational safety and health management system. |

Adjust as needed in response to changes in circumstances and information. |

|

Safety of Port Operations

To secure port area operations, our company employs traffic flow design and port area signage to reduce potential hazards during port and service operations. During 2024, we complied with all relevant regulations and did not violate any laws or regulations related to product and service information and signage or marketing and communication. Specific measures are as follows:

|

Location |

Preventive measure |

|

Keelung Port |

Customs clearance guidance, barrier-free facilities, signage in four languages, safety signs, and sidewalk installation |

|

Taipei Port |

Customs clearance guidance, barrier-free facilities |

|

Su’ao Port |

Customs clearance guidance, barrier-free facilities, Chinese and English signage with flexible language options, pedestrian walkways and safety monitoring, and terminal loading capacity signage. |

|

Taichung Port |

Customs clearance guidance, barrier-free facilities, terminal loading capacity signage. |

|

Kaohsiung Port |

Customs clearance guidance, traffic separation, and restricted access signs for work areas, load restriction notices, and signage maintenance mechanisms. |

|

Anping Port |

Vehicle and pedestrian separation and dispatch signage in the work area |

|

Budai Port |

No entry signs for work areas, traffic separation and dispatch signs, warehouse loading limit signs |

|

Penghu Port |

Customs clearance guidance, barrier-free facilities, loading capacity signs at terminals/warehouses/open storage areas |

|

Hualien Port |

Loading capacity signs at terminals/warehouses/open storage areas (based on the assessment results of professional consultants) |

Education and Training

With the aim of enhancing employees' occupational safety and health knowledge and skills, the Port Authority has been conducting various educational training programs and promotional activities focusing on 'workplace safety' and 'health promotion' to reinforce safety awareness and personal health management capabilities. The company also encourages employees to promote a workplace safety culture through care, communication, and safety observation behaviors. It guides subsidiaries, contractors, and port cargo handling operators to jointly improve occupational safety and health management standards, fostering a safety culture that respects life and demonstrating a commitment to sustainable operations.

Each department shall compile an annual education and training plan based on actual needs, with the primary target audience being our company's employees. As appropriate, public and private sector operators in the port area and stakeholders may also be included. Courses include both internal and external trainings, all of which are conducted by instructors with professional qualifications. For details on the education and training activities conducted in 2024, detailed information is provided in the "Occupational Safety and Health Training." section under " Sustainability Information Disclosure-Friendly Interactive Information" on the TIPC Sustainability website.

|

Internal training |

General or specific occupational safety and health education/training, health seminars, internal audits training for occupational safety and health, regulatory identification training, hazard identification and risk assessment training, and occupational safety and health education/training for relevant personnel involved in related operations. |

|

External Training |

Depending on the requirements of the supervisory authority or the business needs of each unit. |

Employee Health Management

To implement the health policy goal of 'zero occupational diseases', TIPC has established 'Employee Health Management Procedures' and an 'Employee Health Service Plan'. This plan covers all employees within the company, and health checkup expenses are allocated annually to provide employees with free health checkups. The scope and frequency of these check-ups exceed current legal requirements, demonstrating the company's commitment to caring for employee health.

.png)

Employee Health Services Project

All occupational safety and health units within TIPC have dedicated health care personnel responsible for employee health assessments, management, and follow-up. They plan and implement annual health service programs. Assessment content covers ergonomic hazards, unlawful assault, prevention of abnormal workloads, maternal protection, and the health of middle-aged and elderly employees. The company conducts regular general and special occupational health examinations annually (including noise, dust, abnormal air pressure, and long-term night shifts) and has established a Health Management Service Center, where professional nurses provide health consultations. Additionally, the company has specially appointed occupational medicine specialists and on-site physicians to offer one-on-one consultations and follow-ups. Health examination data is uniformly imported into the 'Health Management Information System' for risk grading and management. Recent participation rates in health examinations are as follows: 1,001 people in 2022 (participation rate of 97.18%), 1,071 people in 2023 (98.1%), and 1,031 people in 2024 (99.22%). A total of 8 people did not get examined, with 3 due to physical reasons and 5 due to personal factors. Both the participation rate and the quality of health management have remained high. For details on the number of employees who received health checkups and the associated costs in 2024, detailed information is provided in the "Employee Health Checkups." section under "Sustainability Information Disclosure-Friendly Interactive Information" on the TIPC Sustainability website.